Technology

Our technology platform integrates advanced motion technologies and state-of-the-art CNC tools with an innovative algorithm-based control system and a proprietary chatter suppression solution.

Developing mobile and laser-guided CNC-robotic milling machines for automated, single-pass operation weld profiling and fatigue strength improvement in large steel structures is, first and foremost, a physics challenge.

Our proprietary chatter suppression solution prevents resonance vibration and ensures productivity and quality across weld geometries and according to program.

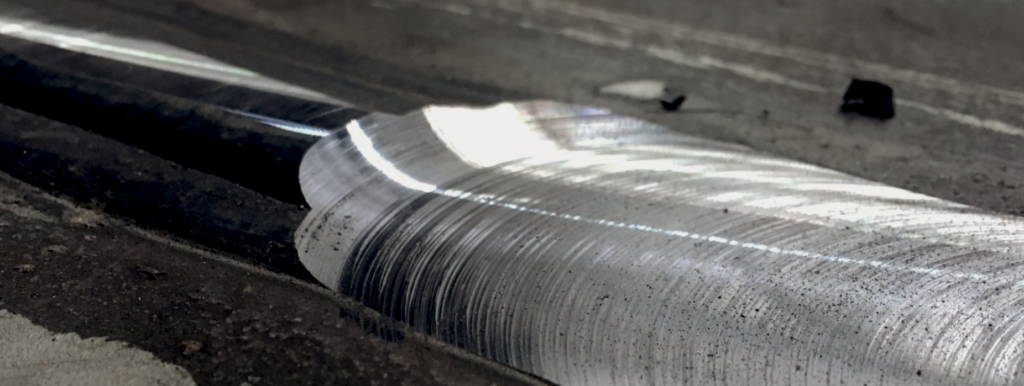

Stop grinding and start machining

A CNC-robotic technology platform for high rate, lower cost and repeatable quality weld profiling

Our technology platform integrates advanced motion technologies and state-of-the-art CNC tools with an innovative algorithm-based control system and a proprietary chatter suppression solution for preventing resonance vibration.

The platform enable us to design, build and customise weld profiling robots bringing high-rate and CNC-quality weld profiling and fatigue strength improvement to the production of large steel structures.

With the MAX TM401 milling robot we address weld profiling and fatigue strength improvement of inside and outside circumferential welds in wind turbine support structures.

Future version of our robot and chatter suppression technology are planned and will bring CNC-robotic weld profiling to butt and filled welds in ship and bridge span structures.

For every action, there is an equal and opposite reaction!

Developing mobile and laser-guided CNC-robotic milling machines for automated, single-cycle operation weld profiling and fatigue strength improvement in large steel structures is also a physics challenge.

Newton’s third law governs the action-reaction pair of forces that milling tools and steel structures exert on each other. Successfully managing that interaction force pair and preventing resonance vibration is a prerequisite for delivering intelligent, algorithm-based weld profiling and fatigue strength improvement at high rate and in uniform quality.

Our proprietary chatter suppression solution prevents resonance vibration and ensures productivity and quality across weld geometries and according to program.

Book here

We are currently offering to demonstrate the MAX TM401 CNC-robot to producers of monopiles, transition pieces and towers at their European production sites.

To inquire and to book a demonstration, please fill in and send the below form. We will get back to you with more details.